Rope Drive Center

The Institute of Mechanical Engineering has various test rigs and measuring equipment to investigate the properties of ropes, the individual components of the rope drive and the system behavior.

-

Various tests can be carried out with the spooling test rig. The stresses in the winch drum (drum shell, flanged sheaves) can be measured at up to 64 positions on the rope drum using strain gauges. The analytical and numerical calculations can thus be verified by the actual stresses or stresses at singular points can be determined. In addition, the winding behavior (spooling behavior) of ropes in multi-layer winding can be investigated.

The test rig has both a hydraulic and an electric drive. With the hydraulic system, rope diameters from 12 to 32 mm can be spooled at up to 40 m/min. The maximum rope tensile force is 300kN. With the electric drives, very energy-efficient continuous operation is possible, as the motors are electrically tensioned against each other. With a maximum rope tensile force of 30 kN and a maximum spooling speed of 15 m/min, the electric drives are suitable for smaller rope diameters up to approx. 12 mm.

By installing a module, rope ageing can be significantly accelerated by increasing the number of bending cycles, so that the spooling behavior and rope properties can be examined over the entire rope service life with a reasonable amount of time.

-

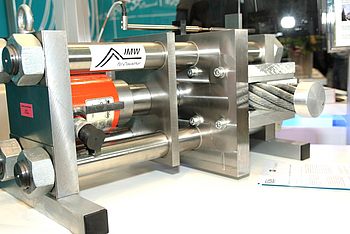

The transverse elasticity of a rope has a significant influence on the load or stress on the rope drum. This knowledge is therefore of particular importance, but is only rarely provided by the rope manufacturer. As the transverse stiffness of ropes depends significantly on the rope tensile force, it is measured under various longitudinal and transverse loads. Up to six ropes can be clamped in the test rig at the same time. This allows not only the stiffness of a single rope to be investigated, but also for the pyramidal and stacked arrangements that occur in the parallel and crossing areas of a system groove. Ropes up to a diameter of 32 mm can be examined at the Institute of Mechanical Engineering. A mobile transverse testing device is available for larger diameters.

-

A mobile transverse testing device is available for rope diameters from 32 mm to 100 mm. The longitudinal load of the rope is applied to a tensile testing machine at the customer's premises. The stiffness of a single rope can then be determined using the transverse testing device. A maximum transverse force of 500kN can be applied.

-

The laser scanners can be used on both the transverse elasticity test rig and the spooling test rig. In the elasticity test, the elastic and plastic deformation of the rope due to the transverse force is examined. On the spooling test stand, the spooling pattern can be determined depending on the layer and then statements can be derived regarding the spooling quality.

For questions about the Rope Drive Center, please contact us by e-mail: